The sintering process

Raw material

The production of a sintered part begins with the careful selection of the raw material, usually an atomized powder of iron, steel, bronze, stainless steel or other specific materials, which can be subsequently mixed according to customer specifications.

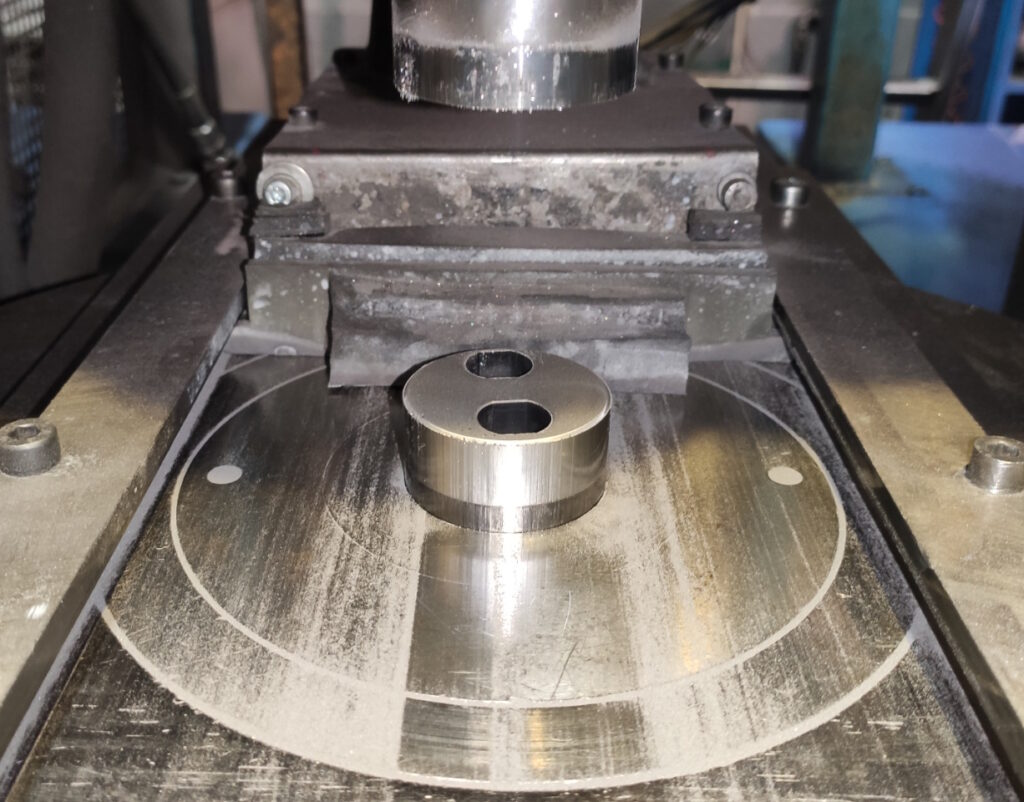

Pressing

The parts are then molded using specially designed and manufactured moulds, mounted on hydraulic or mechanical presses.

During this phase, the products are called “green“, as they have not yet undergone the sintering process, geometrically finished but still mechanically unusable.

The duration of the formation in the press is the same for all products, ranging from simple bushings to complex helical gears, for this reason sintering offers a huge economic advantage, reaching a price reduction of up to 80%.

Sintering

Subsequently, the parts are subjected to the sintering process, which takes place in a specially designed furnace.

The process brings the parts to the sintering temperature, approximately 1130 degrees, and then they are cooled down gradually to avoid creating internal tensions.

Once this process is complete, parts are ready.

We can perform any further processing, such as heat treatment, galvanic, mechanical processing or resin impregnation.

We offer a comprehensive network of specialist contractors to ensure that each subsequent process is carried out with the utmost precision and quality.

If technically feasible, the sintered solution is certainly the best.

“From when the raw material arrives to when the part leaves the company, strict quality controls are carried out at the same time”